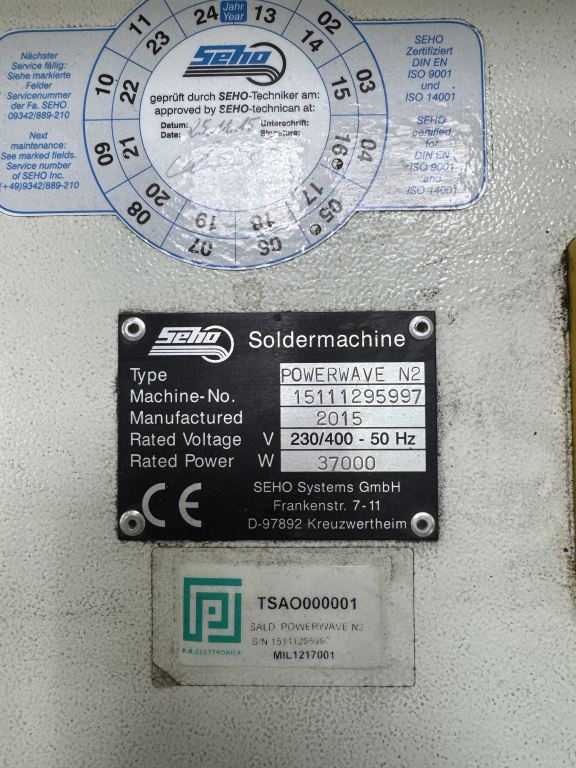

SEHO - Vague Powerwave N2

- S/N 15111295997 / Vintage 2015 - Refurbished in 2025

- Dimensions : L 4400 mm x w 1625 mm x H 1410 mm / Empty weight 1500 Kg

- Full tunnel inerted wave

- Carrier dimensions: Length 500 mm x Width 400 mm

- Conveyor left to right :

=> Free rolls for carriers on the fluxing & pre heating zones

=> Fingers L & V on the process area (above the pot)

* Fixed conveyor width: 400 mm

* Conveyor speed: 0.5 - 2.5 m/min

* Conveyor elevation: 940 mm

* Max. component height : 90 mm

- Fluxer area:

* ATS spray fluxer with HVLP spray head

* Offset and spray width individually programmable

* Atomatic filling by electrical pump

Preheat area:

* Full tunnel preheating / preheating length : 1800 mm

* Number of preheat zones : 6 - Width 300 mm

* 1 x convection (bottom) - 1 x 10.0 KW

* 4 x IR (bottom )- 3 x 3.0 KW

* 1 x quartz (bottom) -1 x 3.75 KW

- Soldering Module:

* 1 ROHS pot

* Carbon steel with ceramic treatment

* Nozzle width: 450 mm

* Solder volume : 620 Kg (lead free)

* Power rating: 9.0 KW

* 1 SMT nozzle EnergyWave 45

* 1 laminar nozzle Delta

* Motorized extraction of the pot from the rear of the machine

* Solder level control

* Solder bar supply (1 to 2 Kg bars)

- Carriers can be offered as an option

- PLC controlled wave

- SMEMA interface

- Automatic controll of fume exhausts

- PLC controlled PCS-747 (touchscreen)

- HMI interface screen on PCS-747 moving support

- Emergency stop push button

- 3 colors beacon with buzzer

- Connections:

* Power inlet: 400 Volts / 3PH - 37KW

- Steady state consumption: 9KW

* Nitrogen connection: 6 bars / 12 à 15 m3/heure

- Compressed air connection : 6 bars

- Exhaust connection : Diam. 200 mm / 1000 m3/hour

machine_contact

Contact us

Refurbished

Thorough check-up of the equipment before complete refurbishment in our workshop, carried out by a highly skilled team, eventually tested before release & shippment

Installed in your factory

Material release, setting on the SMT line and start-up of the equipment carried out by a skilled & experienced engineer. We can also assist you during the start-up of production.

Training included

User training, programming & maintenance training ensured by a skilled engineer

Guarantee

All products are guaranteed to ensure the continuity of production, similar to what you would expect from a brand new equipment

Financing

We offer a quick turnkey solution which will safeguard your capex capability for other invests

Maintenance contract

Preventive annual maintenance to guarantee your production continuity and significantly decrease the maintenance cost of your SMT production line