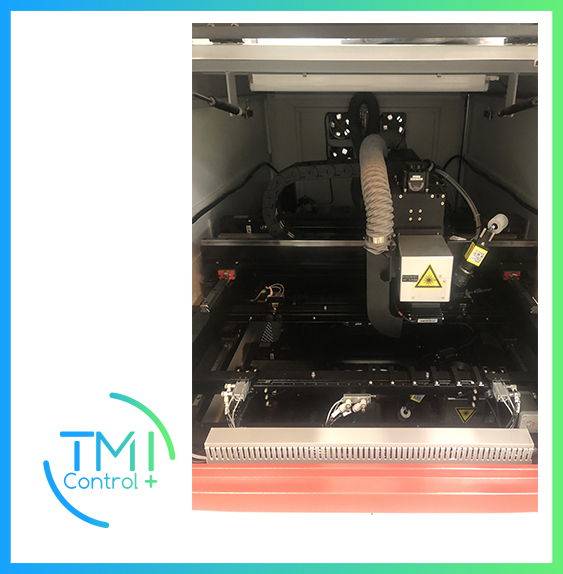

Laser GGTECH - LCB 10C D Dual Head Laser Marking Machine

- Demo machine, vintage 2021

- Dual source laser marking system allowing simulatneous marking on both sides of the PCB

- Overall dimensions (L) 1000 mm x (W) 1600 mm x (H) 1500 mm

- Weight: 1200 Kg

- Standard features:

* Automatic marking with high precision & efficiency CCD positioning system able to check the code after marking process

* Conveyor can be connected with SMT production line

- Friendly HMI

- CO2 10W SYNARD laser source/ 10600 nano m wave length

- Life time: > 45,000 hours in operation

- RAYLASE galvanometer, speed up to 7000 mm

- Cognex industrial camera 2 M Pixels

- Conveyor running direction: L to R or R to L

- Adjustable conveyor width

- Tranport height: 870 mm - 930 mm

- Board dimensions:

* Min/Max: 50 x 50 mm - 460 x 510 mm

* Thickness: 0.5 à 3 mm

- Minimum marking dimensions: 2 mm x 2 mm

- Repeat positioning accuracy: +/- 0.1 mm (CCD camera)

- Support marking code: Code128, code 39, DataMatrix, QR code

- Power supply: 220 V / 50Hz / 2.5 KVA

- Pressurized air: 0.5 - 0.7 MP

- SMEMA interface

- Integrated fume extraction system APT - HP255

* Max flowrate: 250 m3/heure

* Pre filter and main filter

* HEPA filter can filtrate 9.997% of particules with diameter > 0.3 micro m

* Power supply: 380 V / 50Hz / 2.6 KW

* Sound rating: 66dB

* Variable spêed driver system

* Dimensions: (l) 500 mm x (p) 480 mm x (H) 1240 mm

* Weight: 100 Kg

machine_contact

Contact us

Refurbished

Thorough check-up of the equipment before complete refurbishment in our workshop, carried out by a highly skilled team, eventually tested before release & shippment

Installed in your factory

Material release, setting on the SMT line and start-up of the equipment carried out by a skilled & experienced engineer. We can also assist you during the start-up of production.

Training included

User training, programming & maintenance training ensured by a skilled engineer

Guarantee

All products are guaranteed to ensure the continuity of production, similar to what you would expect from a brand new equipment

Financing

We offer a quick turnkey solution which will safeguard your capex capability for other invests

Maintenance contract

Preventive annual maintenance to guarantee your production continuity and significantly decrease the maintenance cost of your SMT production line